ACRI-BOND UV3232

ACRI-BOND UV3232 – UV LIGHT CURING ADHESIVE HIGH VISCOSITY: 900±100 (CPS@25℃) is developed for use in bonding a variety of plastic such as ABS, PC, PS, PVC and Acrylics.

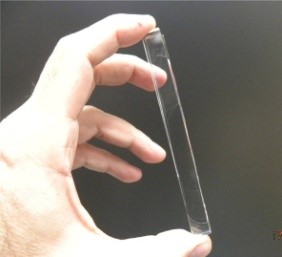

The adhesion strength of ACRI-BOND UV3232 is stronger than the original materials. ACRI-BOND UV3232 is an excellent Photo-curing adhesive and the adhesion strength is stronger than the original materials. The thin film of ACRI-BOND UV3232 is transparent and clear.

Characteristics of ACRI-BOND UV3232

- Toughness, shock resistance and thermal shock resistance.

- Excellent surface dryness and transparency after curing.

- Exhibits high adhesion strength

Physical Property

| Item | Specification | Test Method |

|---|---|---|

| Composition | Acrylic resin | Be judged by the composition |

| Chemical Class | Liquid @ 25°C | Eye inspection |

| Appearance | Colourless Liquid | Eye inspection |

| Viscosity, cps | 880-1320 (25°C S21)10 rpm) | Brookfield RVDV-I+ |

| Specific Gravity | 1.042 @25°C, RH 60% | Specific Gravity Cup |

| Refractive Index nD | 1.4724 @25°C, RH 60% | ATAGO Abbe Refractometer NAR-1T |

| Colour Gardner Scale | 1~2 | Gardner Colour Comparator |

| Solvent Content, % | 0 | Be judged by the composition |

| Heavy Metal Content | 0 | SGS Certificate |

Cure Schedule

Light hardness condition with the ultraviolet ray light source of wave-length 365 nm。 Projecting light upon the energy accumulates to go to 1,500-3,000 mJ/cm 2 of hardening under condition.

| Temporary curing time sec | 5 ~ 10 |

| Recommended curing time sec | 10~ 15 |

Mechanical Properties

| Item | Specification | Test Method |

|---|---|---|

| Durometer Hardness Shore D | D38 @25°C, RH 60% | Durometer D type Refer to ASTM D2240-03 |

| Water Absorption Ratio % | 1.63 @ 25°C 24hr | Refer to ASTM D570-95 |

| Elongation (25°C) , % | 79 | GOTECH GT-TS-2000-M, GOTECH U55 |

| Light Transmittance | JASCO Model V-530 | |

| Glass Transition Temp. °C | -12 | TA instrument MDSCQ100 |

| Temperature Range | -40~110 °C |

ACRI-BOND UV3232 Water-resistant Photo-curing Adhesive for Plastics Bonding

Environmental Test Experiment

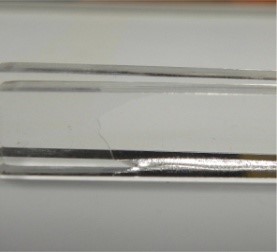

Material:PMMA / PMMA

Condition:60℃ RH 95%

Test Time:2 years, Pass

Result:PMMA crack, no cohesive failure, no leak.

Storage and Shelf Life

ACRI-BOND UV3232 should be kept without any possibility of light exposure. Replace lid immediately after use. ACRI-BOND UV3232 has an eight month minimum shelf life when stored in dark place below 25℃ in original, unopened containers.

Caution

Some findings indicate a lack of potential for carcinogenicity with the compositions of ACRI-BOND UV3232 by long term recurrent application to the skin. However, contact with skin is likely to produce mild transient reddening. It is important to remove adhesive from skin with soap and water thoroughly. ACRI-BOND UV3232 is of moderate acute toxicity by swallowing. If swallowed, induce vomiting at once and call a physician. Avoid contact with eyes. In case of contact, flush with water for at least 15 minutes and get medical attention immediately. For specific information on this product, consult the Material Safety

MSDS Download: ACRI-BOND UV3232 MSDS

MSDS Download: ACRI-BOND UV3232 MSDS